#MS 832 #MS 1017 #PPS

11-Jan-2024

#MS 832 #MS 1017 #PPS

11-Jan-2024

#PPS #MS 832 #MS 1017 #SIRIM PC #SIRIM

Receiving PPS Certificate from CIDB General Manager for Standard & Construction Material Division

Sr Nazir Muhamad Nor

PPS Certificate

Certificate of Standard Compliance or

Perakuan Pematuhan Standard (PPS)

SIRIM Product Certificate

as complying with MS 832:2022

SIRIM Product Certificate

as complying with MS 1017:2022

Design, Supply & Install Façade, Aluminium & Glazing Works For PUTRAJAYA HOLDING BHD & TRC CORP BHD & CHINA STATE CONSTRUCTION ENGINEERING (M) Sdn Bhd

Facade and interior works completed in 2017 for mall and office, tower block completed in 2018.

Scope of works include aluminium windows, doors, louvres, sunshade, screen wall, canopy, expanded metal, cladding, perforated panel, link bridge, glass / stainless steel railing, spider frameless glass wall, ventilation aerofoil louvre, metal screen gratings….

Our facade works include sunshade, Canopy, louvres, claddings, windows, doors, ribbon wall, roof top signage backdrop and walkway……..

The most used engineering terminology can be confusing to the average consumer. Understanding the common jargon used in Façade Engineering can help you communicate with your architect, engineer, or construction manager more effectively.

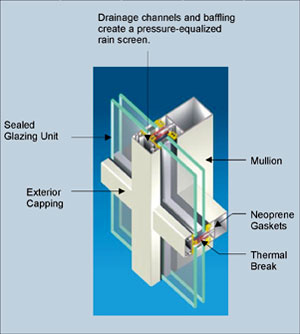

A rainscreen is an exterior wall detail where the siding (wall cladding) stands off from the moisture–resistant surface of an air barrier applied to the sheathing (sheeting) to create a capillary break and to allow drainage and evaporation. The rain screen is the siding itself[1] but the term rainscreen implies a system of building. Ideally the rain screen prevents the wall air/moisture barrier on sheathing from getting wet. In some cases a rainscreen wall is called a pressure-equalized rainscreen wall where the ventilation openings are large enough for the air pressure to nearly equalize on both sides of the rain screen,[2] but this name has been criticized as being redundant[3] and is only useful to scientists and engineers

Air pressure difference is one of the dominant forces for driving a rainwater into wall systems.[11] A rainscreen drainage plane that works as a predictable pressure equalization plane creates a separation (an air chamber) between the backside of a rainscreen and the exterior surface of the weather-resistant barrier that is installed on the exterior sheeting of the structural back up wall. This separation allows air contaminated with water vapor from all points in that wall system to exit the interior of the wall system. Moisture laden air that is allowed to pressurize will attempt to move to a lower pressure area that may be deeper into the interior of a wall detail.

http://buildingscience.com/documents/insights/bsi-004-drainage-holes-and-moderation

Air infiltration is the air which passes through the curtain wall from the exterior to the interior of the building. The air is infiltrated through the gaskets, through imperfect joinery between the horizontal and vertical mullions, through weep holes, and through imperfect sealing. The American Architectural Manufacturers Association (AAMA) is an industry trade group in the U.S. that has developed voluntary specifications regarding acceptable levels of air infiltration through a curtain wall. This limit is expressed (in the USA) in cubic feet per minute per square foot of wall area at a given test pressure. (Currently, most standards cite maximum of 0.06 CFM/sq ft at a pressure of at least 1.57 psf or higher as acceptable.) Testing is typically conducted by an independent third party agency using the ASTM E-783 standard.

One of the disadvantages of using aluminum for mullions is that its modulus of elasticity is about one-third that of steel. This translates to three times more deflection in an aluminum mullion compared to the same steel section under a given load. Building specifications set deflection limits for perpendicular (wind-induced) and in-plane (dead load-induced) deflections. It is important to note that these deflection limits are not imposed due to strength capacities of the mullions. Rather, they are designed to limit deflection of the glass (which may break under excessive deflection), and to ensure that the glass does not come out of its pocket in the mullion. Deflection limits are also necessary to control movement at the interior of the curtain wall. Building construction may be such that there is a wall located near the mullion, and excessive deflection can cause the mullion to contact the wall and cause damage. Also, if deflection of a wall is quite noticeable, public perception may raise undue concern that the wall is not strong enough.

Deflection limits are typically expressed as the distance between anchor points divided by a constant number. A deflection limit of L/175 is common in curtain wall specifications, based on experience with deflection limits that are unlikely to cause damage to the glass held by the mullion. Say a given curtain wall is anchored at 12 foot (144 in) floor heights. The allowable deflection would then be 144/175 = 0.823 inches, which means the wall is allowed to deflect inward or outward a maximum of 0.823 inches at the maximum wind pressure. However, some panels require stricter movement restrictions, or certainly those that prohibit a torque-like motion.

Deflection in mullions is controlled by different shapes and depths of curtain wall members. The depth of a given curtain wall system is usually controlled by the area moment of inertia required to keep deflection limits under the specification. Another way to limit deflections in a given section is to add steel reinforcement to the inside tube of the mullion. Since steel deflects at ⅓ the rate of aluminum, the steel will resist much of the load at a lower cost or smaller depth.

A louver is provided in an area where mechanical equipment located inside the building requires ventilation or fresh air to operate. They can also serve as a means of allowing outside air to filter into the building to take advantage of favourable climatic conditions and minimize the usage of energy-consuming HVAC systems. Curtain wall systems can be adapted to accept most types of louver systems to maintain the same architectural sightlines and style while providing the necessary functionality.

Most curtain wall glazing is fixed, meaning there is no access to the exterior of the building except through doors. However, windows or vents can be glazed into the curtain wall system as well, to provide required ventilation or operable windows. Nearly any window type can be made to fit into a curtain wall system.

Beam

A structural member, usually horizontal, with a main function to carry loads cross-ways to its longitudinal axis. These loads usually result in bending of the beam member. Examples of beams are simple, continuous, and cantilever.

Beam-Column

This is a structural member whose main function is to carry loads both parallel and transverse to the longitudinal axis.

Cantilever

Cantilever refers to the part of a member that extends freely over a beam, which is not supported at its end.

Collateral Load

Collateral load is additional dead loads (not the weight of people and not the weight of the building itself), such as plumbing, duct work, ceilings, and other components of the structure.

Column

A column is a main vertical member that carries axial loads from the main roof beams or girders to the foundation parallel to its longitudinal axis.

Continuity

Continuity is the term given to a structural system describing the transfer of loads and stresses from member to member as if there were no connections.

Damping

Damping is the rate of decay of amplitude for floor vibrations.

Dead Load

Dead load describes the loads from the weight of the permanent components of the structure.

Deflection

Deflection is the displacement of a structural member or system under a load.

Dynamic Load

This type of load varies over time.

Footing

A footing is a slab of concrete under a column, wall, or other structural to transfer the loads of the member into the surrounding soil.

Foundation

A foundation supports a building or structure.

Header

A member that carries other supporting members and is placed between other beams.

Joist

A structural load-carrying member with an open web system which supports floors and roofs utilizing hot-rolled or cold-formed steel and is designed as a simple span member.

Pascal Pa Kilo Pascal = 1000Pa (KPa)

The pascal can be expressed using SI derived units, or alternatively solely SI base units, as:

where N is the newton, m is the metre, kg is the kilogram, and s is the second.[5]

One pascal is the pressure exerted by a force of magnitude one newton perpendicularly upon an area of one square metre.

Live Load

Non-permanent loads on a structure created by the use of the structure.

Load

An outside force that affects the structure or its members.

Modulus of Elasticity (E)

The value is usually 29,000 ksi for structural steels and is also called Young’s Modulus. It calculates the slope of the straight-line portion of the stress-strain curve in the elastic range.

Moment

Moment is the tendency of a force to cause a rotation about a point or axis which in turn produces bending stresses.

Moment of Inertia (I)

A measure of the resistance to rotation offered by a member’s geometry and size.

Seismic Load

Loads produced during the seismic movements of an earthquake.

Shear

Forces resulting in two touching parts of a material to slide in opposite directions parallel to their plane of contact.

Span

The distance between supports.

Structural Steels

Steels suitable for load-carrying members in a structure.

Strut

A structural brace that resists axial forces.

Stud

A vertical wall member used to attach other structures, such as walls.

Torsion Loads

A load that causes a member to twist about its longitudinal axis. A couple or moment in a plane perpendicular to the axis produces simple torsion.

Wind load

Wind load acting on the building is the result of wind blowing on the building. This wind pressure must be resisted by the curtain wall system since it envelops and protects the building. Wind loads vary greatly throughout the world, with the largest wind loads being near the coast in hurricane-prone regions. For each project location, building codes specify the required design wind loads. Often, a wind tunnel study is performed on large or unusually shaped buildings. A scale model of the building and the surrounding vicinity is built and placed in a wind tunnel to determine the wind pressures acting on the structure in question. These studies take into account vortex shedding around corners and the effects of surrounding area

These most used structural engineering terminology definitions provide a baseline understanding of engineering jargon for the average consumer. Detailed definitions can be obtained from visiting a professional engineering website or professional journal.

for further reading please read link below:

[www.FacadeEngineeringSociety.org]

Building facades are one of the largest, most important elements in the overall aesthetic and technical performance of a building. Façade Engineering is the art and science of resolving aesthetic, environmental and structural issues to achieve the effective enclosure of buildings.

Specialist companies are dedicated to this niche sector of the building industry and engineers operate within technical divisions of façade manufacturing companies. Generally, façade engineers are specifically qualified in the discipline of façade engineering and consultants work with the design team on construction projects for architects, building owners, construction managers and product manufacturers.

Façade engineers must consider aspects such as the design, certification, fabrication and installation of the building facades with regards to the performance of materials, aesthetic appearance, structural behaviour, weathertightness, safety and serviceability, security, maintenance and build ability. The skill set will include matters such as computational fluid dynamics, heat transfer through two- and three-dimensional constructions, the behaviour of materials, manufacturing methodologies, structural engineering and logistics.

Over time, the specialist skills necessary in this niche sector have surpassed the capabilities of architects, structural and mechanical engineers as buildings are designed with more complexity and with the introduction of Building Information Modelling (BIM).

Building facades are considered to be one of the most expensive and potentially the highest risk element of any major project. Historically building facades have the greatest level of failure of any part of a building fabric and the pressure for change and adaptation due to environmental and energy performance needs is greater than any other element of a building. As a consequence façade engineering has become a science in its own right.

Façade engineers concern themselves with everything to do with a building’s external envelope above ground level. Many names can be used to describe the envelope, for instance:

Façade Engineers will consider the performance of such materials and systems in various respects:

Façade engineers provide advice on both existing and new buildings. They may be involved in design, working alongside the architect, QS and structural and mechanical engineers, or may work within contracting or manufacturing. Alternatively, they may be involved in surveying or diagnostic and remedial work. Some façade engineers are involved in research and testing.

Façade engineers come from a range of backgrounds but most usually architectural, structural or building physics. In order then to become a facade engineer, they have then developed a wider breadth of cladding skills and a deeper knowledge than they would encounter within their original discipline.

Many façade engineers will be generalist façade engineers. These are able to advise across the full range of materials, systems and performance types.

Specialist façade engineers will typically first have attained a level of knowledge across all façade types and then have chosen to specialise in one particular aspect of façade engineering. Examples are façade engineers whose emphasis is in building envelope physics, using analytical modelling skills; or façade engineers that specialise in a particular cladding material such as stone or glass.

Parallels exist with other professions with generalist and specialist divisions e.g. legal where there are solicitors and barristers, and medicine where there are general practitioners and consultants. It may be difficult for clients at the inception of their project to decide which type of façade engineer they require. A general practice façade engineer is best placed to determine this for the particular circumstances of a client’s individual project and advise on façade specialisms that may be needed.

How does this differ from what others in the design team already do?

Facades have become complicated beyond the skills of architects, structural and mechanical engineers. Facades require a dedicated engineer with a particular range of skills and experience, who understands their behaviour and can undertake their design, manufacture and installation better, more efficiently and more comprehensively than can a traditional architect, structural or mechanical engineer.